Harnessing the Power of Data for Smarter Water Management

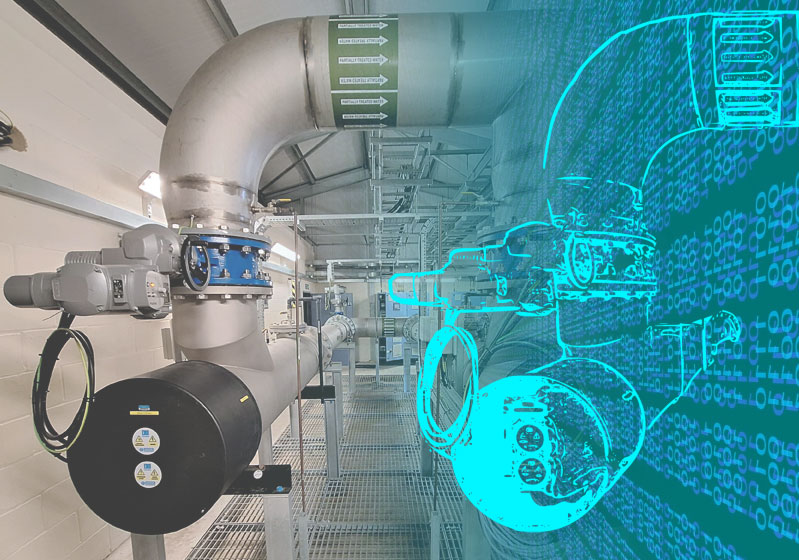

In today’s rapidly evolving technological landscape, the concept of a digital twin is gaining significant traction across various industries. A digital twin is a virtual replica of a physical asset or system, allowing for real-time monitoring, analysis, and optimisation. For water companies, the potential benefits of a digital twin are immense, from improving operational efficiency to enhancing customer satisfaction.

The Benefits of a Digital Twin for Water Companies

- Enhanced Operational Efficiency: A digital twin can provide valuable insights into water distribution networks, enabling companies to identify leaks, optimize water pressure, and minimize leakage. This can lead to significant cost savings and improved resource management.

- Improved Asset Management: By creating digital twins of critical infrastructure, such as water treatment plants and pumping stations, water companies can proactively monitor equipment health, predict failures, and schedule maintenance more effectively.

- Enhanced Customer Service: A digital twin can empower water companies to respond more quickly to customer inquiries and complaints. By having real-time data on water quality and pressure, companies can provide accurate information and address issues promptly.

- Improved Decision Making: A digital twin can support data-driven decision-making by providing valuable insights into complex water systems. Companies can use this information to develop more effective strategies for water conservation, demand management, and infrastructure planning.

Building a Digital Twin: Key Considerations

Creating a digital twin requires a comprehensive approach that involves several key steps:

1. Data Collection and Integration: Gathering and integrating data from various sources, such as sensors, SCADA systems, and historical records, is essential for building a comprehensive digital twin.

2. Modeling and Simulation: Developing accurate models of water infrastructure, including pipes, reservoirs, and treatment plants, allows for simulating different scenarios and evaluating potential outcomes.

3. Visualization and Analytics: Visualizing data and using advanced analytics techniques can help identify patterns, anomalies, and trends within the water system.

4. Integration with Existing Systems: Ensuring seamless integration of the digital twin with existing operational systems and workflows is crucial for maximizing its benefits.

A Case Study: Portsmouth Water’s Digital Twin Initiative

Producing a digital twin of Portsmouth Water’s water supply and distribution system is a significant project which HydroCo are supporting. By rebuilding their entire Hydraulic Modelling coverage to a specifically designed specification and integrating real-time telemetry data, and advanced Model Maintenance they on the path to a robust and future proof digital twin.

HydroCo’s involvement in this project is a strong indication of their expertise in the field of water infrastructure and their commitment to supporting sustainable water management practices. By providing technical support and expertise, HydroCo can help to ensure that the digital twin is built to the highest standards and delivers the maximum benefits to Portsmouth Water.

Conclusion

A digital twin offers a powerful tool for water companies to enhance their operations, improve customer service, and drive sustainability. By harnessing the power of data and technology, water companies can create more resilient, efficient, and sustainable water systems for generations to come.