Background

Air valves, though frequently overlooked, are critical assets in safeguarding water networks from significant damage and operational inefficiencies. They are essential not only for new mains commissioning but also for managing air during and after burst events, releasing air generated by pump cavitation, and providing crucial protection against negative surge pressures. The absence or malfunction of these vital components can lead to severe consequences for the network.

Specifically, trapped air can act as a throttle, impeding flow and reducing efficiency; the oxygen within it can accelerate pipe corrosion; and it can cause meters and control valves to malfunction, leading to inaccurate readings and operational failures. Furthermore, the build-up of pressure from trapped air can result in damaging transient pressures (air hammer), while vacuum conditions can cause catastrophic pipe failures.

Critical air valve protection

Trapped air risks identified

GIS and LiDAR integration

Optimised valve placement recommendations

Our Approach

Assessing and optimizing air valve networks involves a systematic process to identify critical areas and ensure optimal valve placement and type.

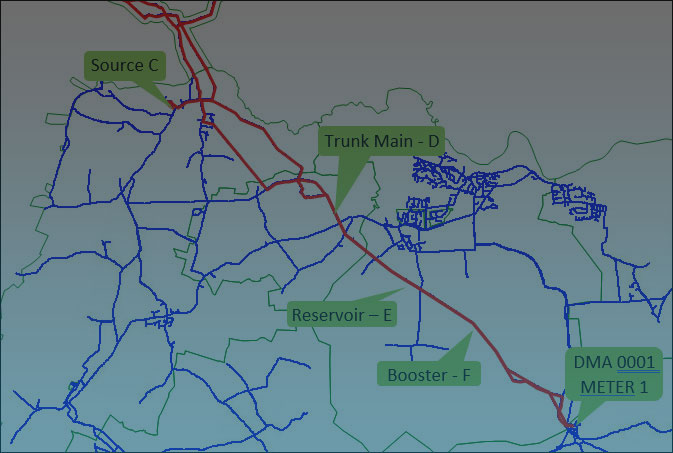

Firstly, we categorize DMAs (District Metered Areas) and trunk mains by their risk factor (high, medium, or low). For instance, a pumped trunk main inherently presents a higher risk profile than a gravity main due to increased potential for surge issues.

Given that air valve locations are typically not included in the model, we begin by importing existing valve locations into the network from GIS data. To ensure the accuracy of our analysis, it’s crucial that network elevations are correct. We verify nodal elevations using recent LiDAR data. For long stretches of main that require a more granular understanding of high and low spots, we utilise Ruby script and inference tools to subdivide these mains into shorter sections, updating their elevations accordingly.

Finally, we leverage hydraulic models to assess nodal elevations in comparison to existing air valve placements. This allows us to determine if valves are optimally located at critical points such as high spots, low spots, and pump outlets. We also verify that the correct valve type has been selected for each specific application. Where air valves are missing, we provide recommendations for new locations, detailing the necessity for their installation and specifying the appropriate valve type to be used.

If you would like to learn more about how HydroCo can support you with pressure management assessments, please contact us at innovation@hydroco.co.uk or call 023 92 450 007.