HydroCo has successfully developed network models for a significant portion of the UK water industry, encompassing millions of miles of pipeline and customer connections.

Building a network model typically involves two phases, although our approach is flexible to align with our clients’ specific needs. This intricate process spans project durations of 3-9 months.

Phase 1 – Base model creation

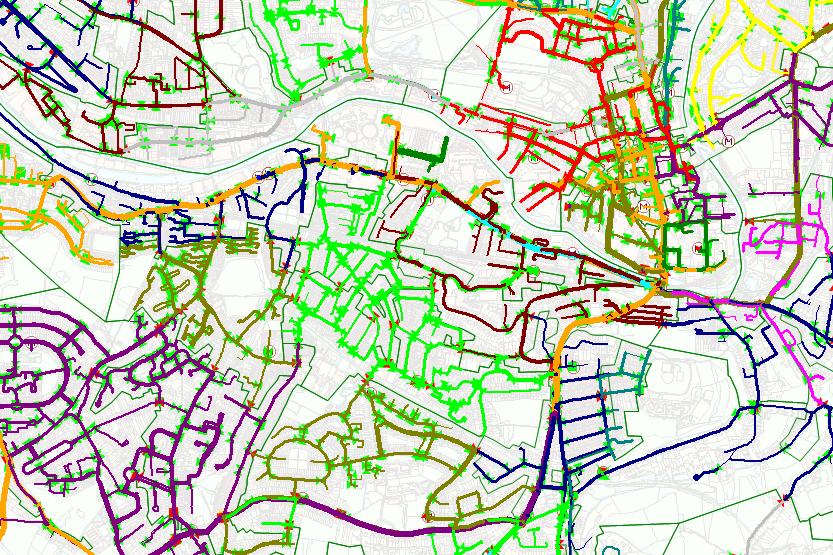

The process commences with the transformation of vital asset data from the organization’s Geographical Information System (GIS) into a format conducive to modelling. HydroCo has crafted a suite of customized conversion tools, enabling us to execute precise and cost-effective GIS conversion routines.

Phase 1 – Data collection and validation

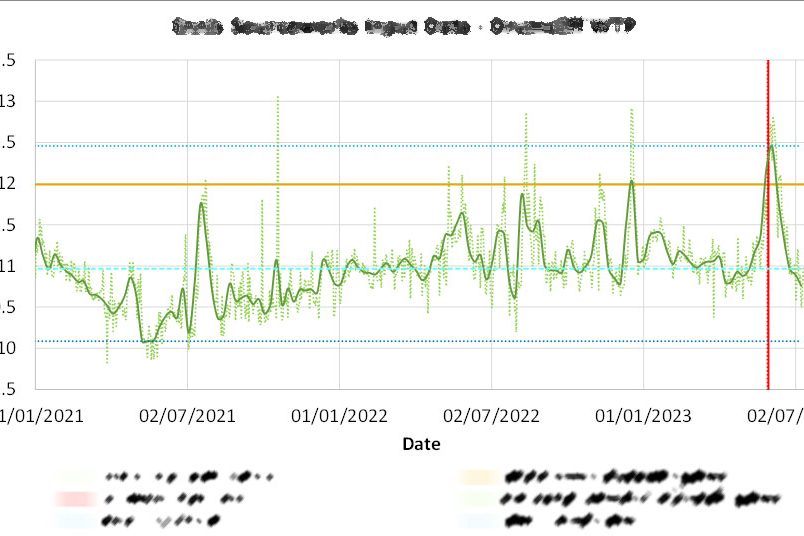

Utilizing historical telemetry data, we conduct a comprehensive analysis and verification process. Initial demands are calculated for each area, and we identify missing flow metering, deriving reservoir and trunk main balances. This desktop analysis is pivotal in comprehending the water network before embarking on any field testing activities, minimizing the need for abortive efforts.

Phase 1 – Operational model

At this juncture, we employ the validated data from the desktop study to construct a fully operational phase 1 model. This step aids in pinpointing any anomalies or inaccuracies in the data before the field test, enabling us to deploy additional loggers during the field test to address and resolve these issues effectively.

Phase 2 – Field Test

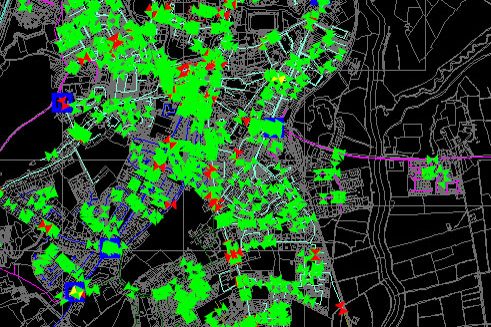

The subsequent phase involves gathering a comprehensive and cohesive dataset to facilitate model calibration. HydroCo conducts all our field tests in-house and is experienced in deploying up to 500 loggers to meticulously capture the detailed operation of a system.

Phase 2 – Data validation & analytics

Similar to the phase 1 exercise, data verification checks are repeated to ensure a high quality data set has been achieved. Providing our clients with insight into potential operationally efficiencies, leakage reduction opportunities and asset performance.

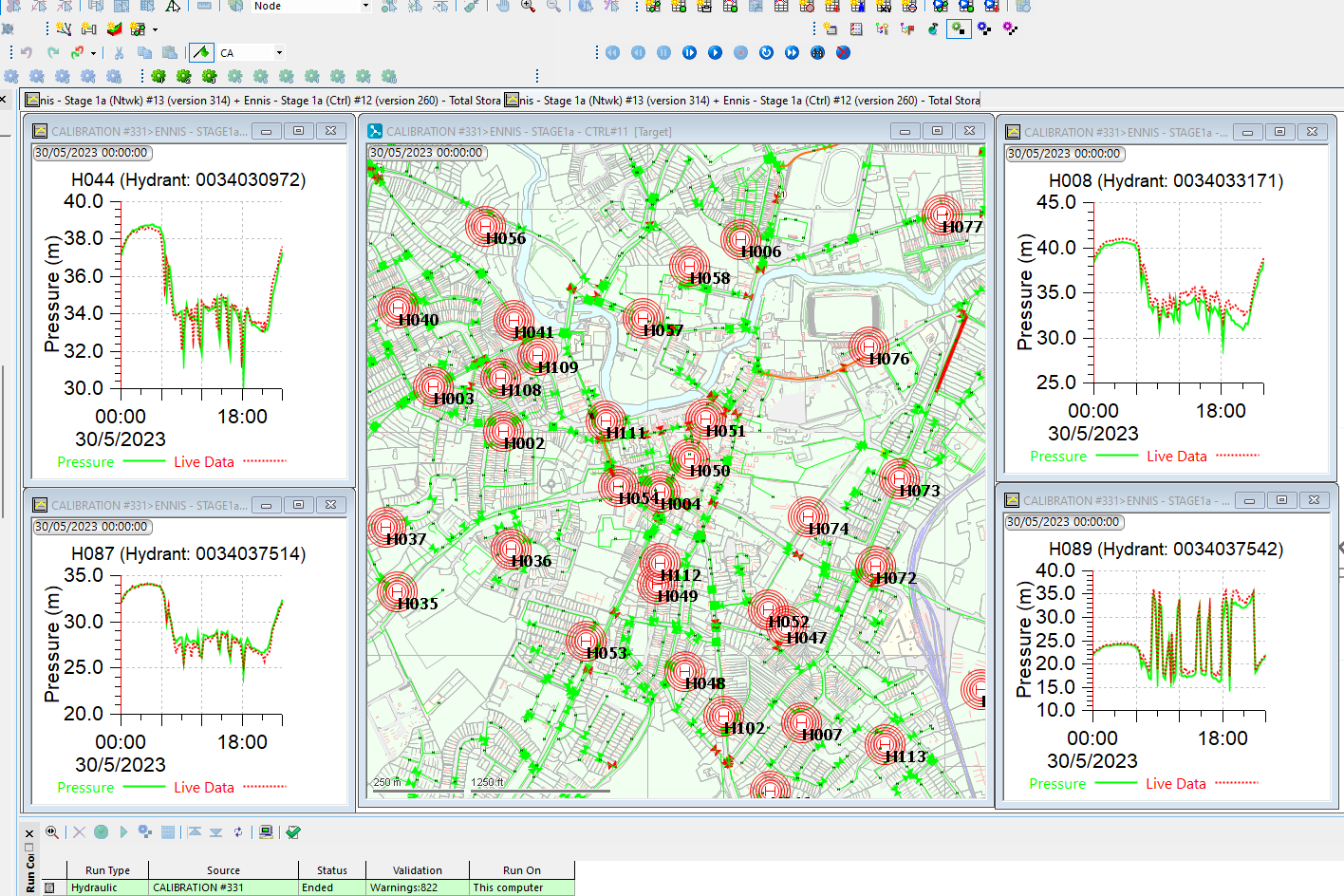

Phase 2 – Model Calibration

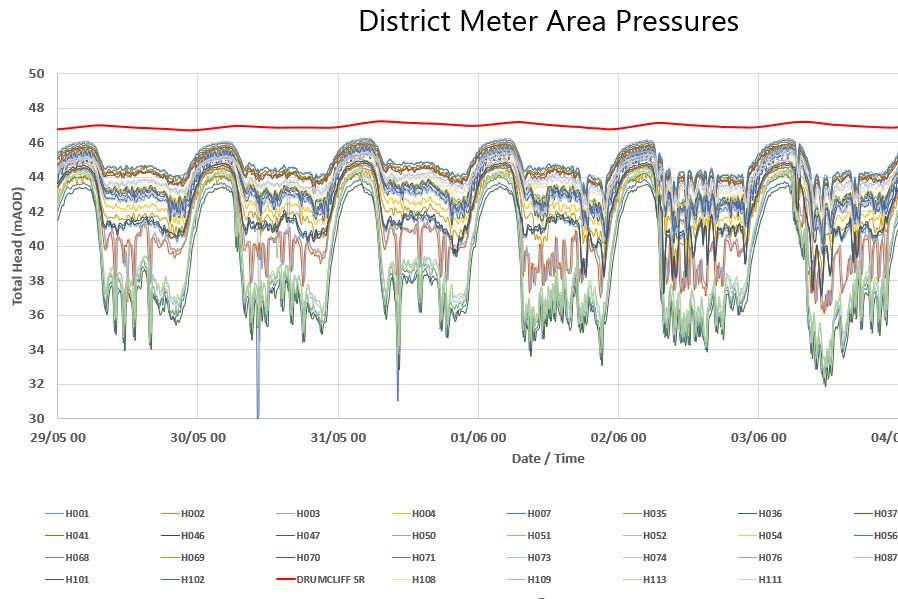

The model results are compared to the field test data, and reasoned adjustments are made to the base model in order to replicate the hydraulics of the system. This is a highly skilful part of the model build process, and performed by our senior staff members, who have a wealth of experience.

Phase 2 – Reporting & Handover

In this pivotal concluding stage, we elucidate the exact methodology employed throughout the project and, more significantly, highlight the challenges encountered during the model build. Our clients value our meticulous reporting process, which not only encompasses the calibration process and system performance but also identifies operational issues and provides recommendations to optimize and enhance the system.